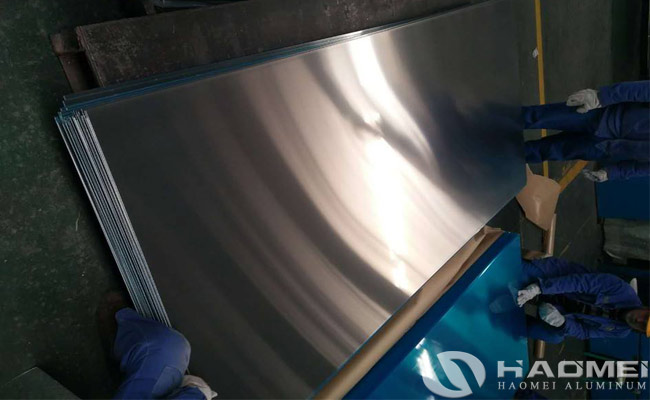

Hot rolled aluminum plate is an aluminum alloy sheet produced through a hot rolling process. The hot rolling process involves heating aluminum ingots to a specific temperature at high temperatures, then pressing and shaping them using a rolling mill. This process refines the grain size of the aluminum, improving its strength and toughness, while also enhancing its plasticity and processing performance.

Specifications of hot rolled aluminum plate:

Hot rolled aluminium plate is produced using a high-temperature rolling process, offering a wide range of specifications to meet the needs of various industries:

– Thickness:

Typically 0.8mm-600mm, with standard thicknesses ranging from 10mm-450mm. Extra-thick aluminum plates can reach 600mm, suitable for high-strength structural components.

– Width:

Standard widths range from 1000mm-2200mm, with a maximum of 2800mm, meeting the needs of wide-format curtain walls, shipbuilding, etc.

– Length:

Length is unlimited and can be customized to meet specific requirements. Standard sizes range from 1000mm×2000mm to 1500mm×3000mm, with extra-long aluminum sheets reaching 11000mm.

Typical materials of hot rolled aluminium plate:

– Pure aluminum series:

1050, 1060, 1070, 1100 (aluminum content ≥99.0%), suitable for applications with lower strength requirements.

– Alloy series:

3003, 3004, 3104, 3105: Rust-resistant aluminum, containing manganese, excellent corrosion resistance.

5005, 5052, 5083, 5086, 5754: Aluminum-magnesium alloy, high strength, resistant to seawater corrosion, suitable for ships and pressure vessels.

6061, 6082, 6063: Aluminum-magnesium-silicon alloy, heat-treatable, used in aerospace and automotive structural components.

7075: Ultra-hard aluminum alloy, high wear resistance, used in high-stress components.

Characteristics of hot rolled aluminum plate:

Hot rolled aluminum plates, due to their technological advantages, possess the following characteristics:

– Excellent surface quality:

High-temperature rolling results in a high surface finish and good oxidation effect, allowing for direct use for decoration or further processing.

– High mechanical properties:

Tensile Strength: 1060 aluminum sheet has a tensile strength of 110-136 MPa, with alloy series reaching even higher strengths (e.g., 5052 can reach 230-280 MPa).

– Dulleriness:

Suitable for complex processing such as stamping, deep drawing, and bending, with good formability.

– Corrosion resistance:

A dense oxide film forms on the surface, effectively preventing corrosion, suitable for humid and acidic environments.

– Lightweight:

Density is only 2.7 g/cm³, about 1/3 that of steel, significantly reducing structural weight.

– Low work hardening:

The softening process dominates during hot rolling, resulting in low deformation resistance, low energy consumption, and high production efficiency.

Application areas of the hot rolled aluminum plates:

Hot-rolled aluminum plates are widely used in scenarios with stringent material performance requirements:

– Construction:

Curtain walls and decoration: Wide-width aluminum sheets are used for building exterior walls and ceilings, such as high-rise building facade decoration and interior decoration.

Structural Support: 5052 and 6061 aluminum sheets are used for bridge and steel structure reinforcement, balancing strength and durability.

– Transportation:

Automotive industry: Lightweighting demands drive the application of aluminum sheets, such as in body panels, hoods, and wheels, reducing fuel consumption.

Aerospace: 7075 aluminum plate is used in aircraft fuselages and wings, while 6061 is used in structural components, meeting high strength and fatigue resistance requirements.

Shipbuilding: 5083 aluminum sheets resist seawater corrosion and are used in hulls and decks, extending service life.

– Electronics & Electrical Appliances:

Heat dissipation components: Pure aluminum sheets (such as 1060) are used in LED lamp holders and electronic heat sinks, offering excellent thermal conductivity.

Casings and structures: 3003 aluminum sheets are used in refrigerator and air conditioner casings, balancing strength and aesthetics.

– Packaging Industry:

Food packaging: 3004 alloy aluminum sheets are used in beverage can materials, providing moisture and oxidation resistance to ensure the safety of the contents.

Pharmaceutical packaging: Aluminum sheets combined with plastics are used in blister packaging for pharmaceuticals, isolating them from light and moisture.

– Chemicals & Energy:

Pressure Vessels: 5052 and 5083 aluminum sheets are used in storage tanks and pipelines, offering resistance to chemical corrosion.

New energy equipment: 6061 alloy is used in solar panel mounting systems and wind power equipment, adapting to harsh environments.

Hot rolled aluminum plates, with their diverse specifications and excellent performance, have become core materials in construction, transportation, electronics, and other fields. Pure aluminum series (such as 1060) are suitable for low-cost decorative applications, while alloy series (such as 5052 and 6061) meet the requirements for high strength and corrosion resistance. With the advancement of lightweighting and environmental protection trends, the application prospects of hot-rolled aluminum plates will further expand, providing key support for high-end manufacturing.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form